A Deep Study the Various Types of Metal Casting and Their Makes use of

Metal Casting encompasses numerous strategies, each customized for specific applications and demands. From the cost-efficient sand casting technique to the precision of financial investment spreading, each process has unique benefits. Pass away casting stands out in high-volume production circumstances, while lost foam spreading presents innovative layout possibilities. In addition, permanent mold and mildew casting is identified for its durability. Recognizing these methods opens up a window into their useful uses and ramifications in numerous industries. What lies under the surface area of these casting methods?

Sand Spreading: A Economical and functional Technique

Different casting techniques exist, sand casting stays one of the most affordable and versatile techniques in the metalworking industry. This method utilizes a mixture of sand and a binding representative to produce molds, enabling for the production of parts in diverse sizes and forms. Sand spreading is particularly helpful for small to tool production runs, as it calls for marginal in advance investment in tooling compared to other casting methods.

The procedure starts with the creation of a mold and mildew, where liquified steel is gathered to develop the desired item once cooled. Its versatility allows making use of numerous steels, consisting of aluminum, steel, and iron. In enhancement, sand spreading can suit complex geometries, making it appropriate for an array of applications, from auto elements to detailed creative pieces. On the whole, sand spreading's effectiveness and flexibility strengthen its significance in the manufacturing landscape.

Investment Casting: Accuracy and Detail for Complicated Shapes

Investment casting stands out as a technique renowned for its capability to generate highly outlined and intricate components. This procedure includes creating a wax pattern that is coated with a ceramic covering, which is after that warmed to get rid of the wax and solidify the covering. The outcome is an accurate mold that can capture complicated geometrical shapes with amazing accuracy.

This casting strategy is particularly advantageous for producing parts with thin wall surfaces, great attributes, and tight tolerances, making it excellent for industries such as aerospace, vehicle, and clinical gadgets. Investment spreading fits a variety of steels, consisting of stainless steel, aluminum, and titanium, allowing suppliers to satisfy details product needs.

The procedure reduces machining demands post-casting, which can boost effectiveness and minimize production costs. In general, investment casting is a preferred option for applications where precision and information are vital.

Pass Away Casting: High-Volume Production With Excellent Surface Finish

Pass away casting is a highly reliable manufacturing procedure that masters creating huge volumes of metal components with phenomenal surface finishes. This technique entails compeling molten steel into a mold cavity under high pressure, permitting for fast production cycles and uniformity in the finished items. Generally used materials consist of magnesium, light weight aluminum, and zinc, which use excellent mechanical residential or commercial properties and rust resistance.

Die spreading is specifically valuable for sectors such as auto, electronic devices, and consumer products, where precision and quality are critical. The process enables detailed styles, decreasing the requirement for added machining and ending up processes. Furthermore, the smooth surface areas produced through die casting often call for marginal post-processing, leading to lower general manufacturing costs. As a high-volume manufacturing method, pass away spreading is perfect for suppliers seeking performance without endangering on quality, making it a recommended option for many applications across numerous industries.

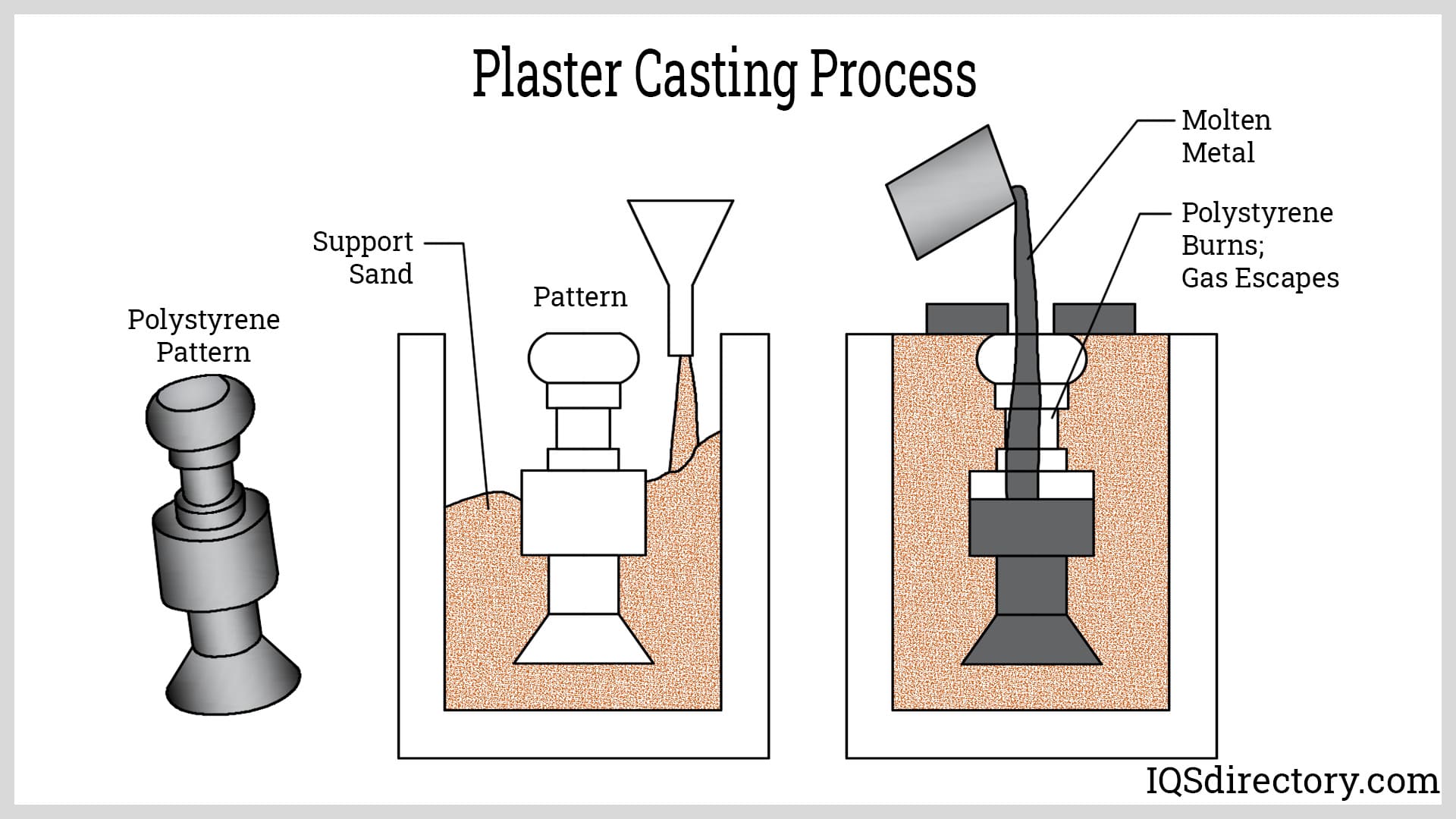

Lost Foam Casting: Innovative Method for Intricate Styles

Lost foam casting changes the production of intricate steel parts by making use of a distinct process that removes the need for traditional mold and mildews. As opposed to traditional mold-making, this method uses a foam pattern that is coated with a refractory material. As soon as the pattern is established, molten steel is put directly into the mold and mildew, triggering the foam to leave and evaporate behind an accurate dental caries for the Wisconsin Aluminum Foundry metal to fill up. This innovative approach enables for elaborate layouts and detailed features that may be challenging to attain with various other casting approaches.

In addition, lost foam casting can decrease waste and power consumption, making it an eco friendly choice. Industries such as aerospace and automobile benefit significantly from this technique, as it sustains the creation of lightweight elements with complex geometries. Generally, shed foam casting sticks out for its ability to deliver high-quality, tailored steel components successfully.

Permanent Mold And Mildew Spreading: Resilience and Consistency in Metal Components

Permanent mold casting is an extremely effective approach for creating sturdy and consistent steel parts, leveraging recyclable mold and mildews that are typically made from steels such as iron or steel. This casting procedure includes putting liquified steel into these mold and mildews, which are preheated to enhance product high quality and lower flaws. The use of recyclable mold and mildews not only decreases waste however likewise enables higher manufacturing rates, making it financially helpful for manufacturers.

The resulting parts exhibit exceptional dimensional precision and surface finish, making them ideal for applications in auto, aerospace, and industrial equipment. In addition, irreversible mold and mildew spreading can accommodate a variety of alloys, even more increasing its versatility. The longevity of the actors parts is boosted because of the controlled cooling rates that promote better grain frameworks. Overall, this spreading method attracts attention for its capability to create top notch steel straight from the source components that satisfy extensive performance requirements, making sure dependability in demanding settings.

Frequently Asked Concerns

What Materials Can Be Made Use Of in Different Steel Casting Procedures?

Various products can be utilized in Metal Casting processes, consisting of aluminum, iron, zinc, and bronze. Each material supplies unique properties, influencing the casting approach's efficiency, toughness, and suitability for different applications in production.

Just How Do Casting Techniques Impact the Mechanical Features of Metals?

Casting approaches significantly affect the mechanical homes of metals, impacting aspects like ductility, strength, and hardness. Variations in cooling down rates and mold materials can lead to different microstructures, eventually affecting the efficiency of the last product.

What Are the Ecological Effects of Metal Casting Processes?

Metal Casting procedures can lead to air and water contamination, resource deficiency, and substantial power consumption (Aluminum Castings). Furthermore, the generation of waste materials and greenhouse gas emissions substantially adds and impacts the setting to environment modification

Just how Do You Select the Right Spreading Technique for a Task?

Picking the best casting technique includes examining task needs, product homes, intricacy, and manufacturing quantity. Aspects like expense performance, surface quality, and preparation additionally play crucial duties in establishing the most suitable method.

What Safety and security Preventative Measures Should Be Taken Throughout Metal Casting Operations?

Throughout Metal Casting procedures, safety precautions include putting on protective equipment, guaranteeing appropriate air flow, carrying out equipment inspections, maintaining a clean work website here space, and having emergency situation protocols in location to deal with possible threats like burns or toxic fumes.

From the economical sand casting approach to the accuracy of investment casting, each procedure has unique advantages. Pass away spreading is a very efficient manufacturing process that stands out in creating big volumes of steel components with exceptional surface area finishes. Lost foam spreading changes the production of complicated steel parts by using an one-of-a-kind procedure that removes the demand for conventional mold and mildews (Wisconsin Aluminum Foundry). Permanent mold spreading is a very efficient approach for generating consistent and durable steel components, leveraging reusable molds that are usually made from steels such as iron or steel. Different materials can be used in Metal Casting procedures, including aluminum, zinc, iron, and bronze